Modeling of Granular Structures

GrainGeo

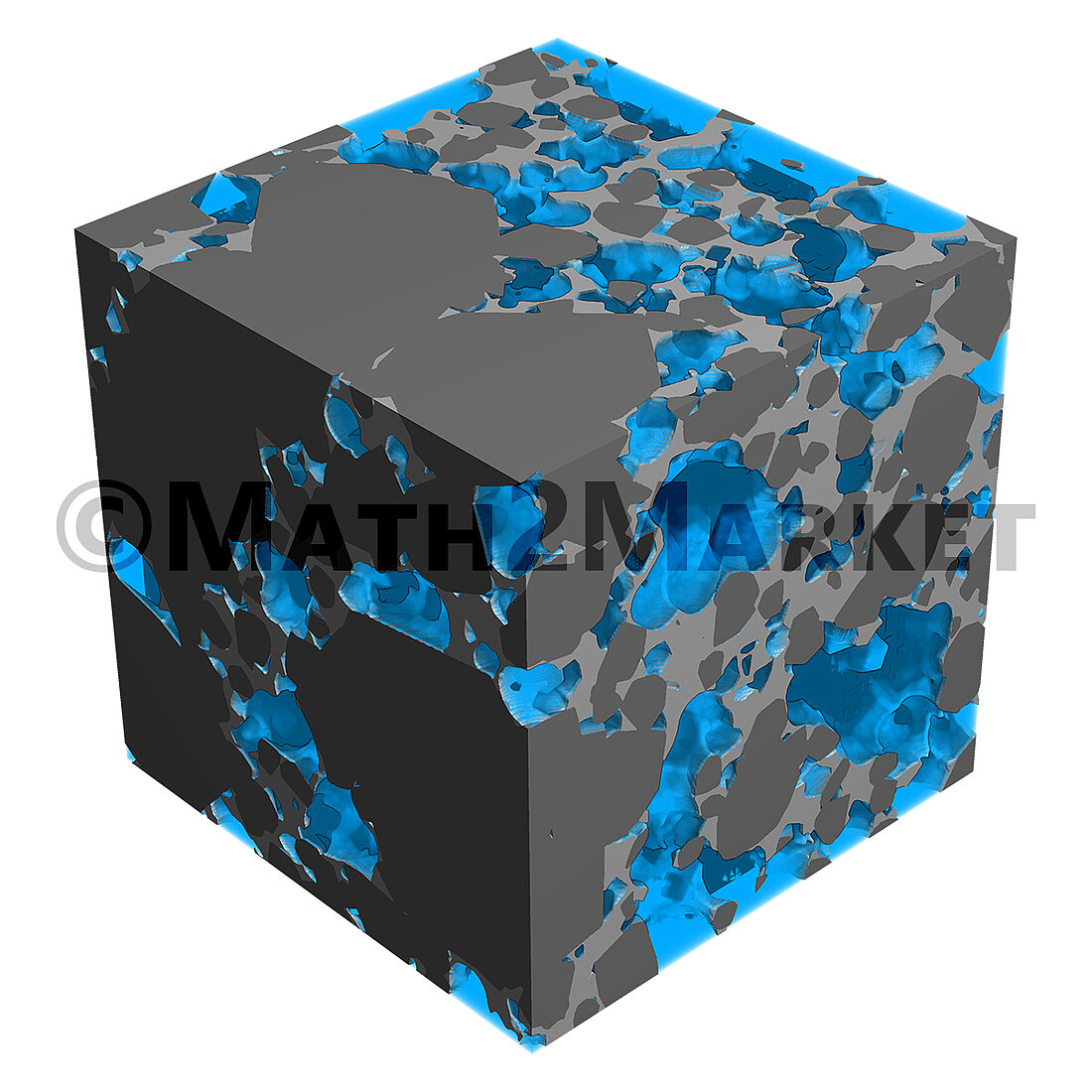

GrainGeo creates advanced digital 3D models of materials (so-called Digital Twins), such as battery and fuel-cell electrodes, catalyst materials, ceramics, rocks, sintered materials, grain packings, or powders. Our modeling process begins with a statistical description of the material, encompassing key parameters like grain size distribution, pore size distribution, and grain shapes.

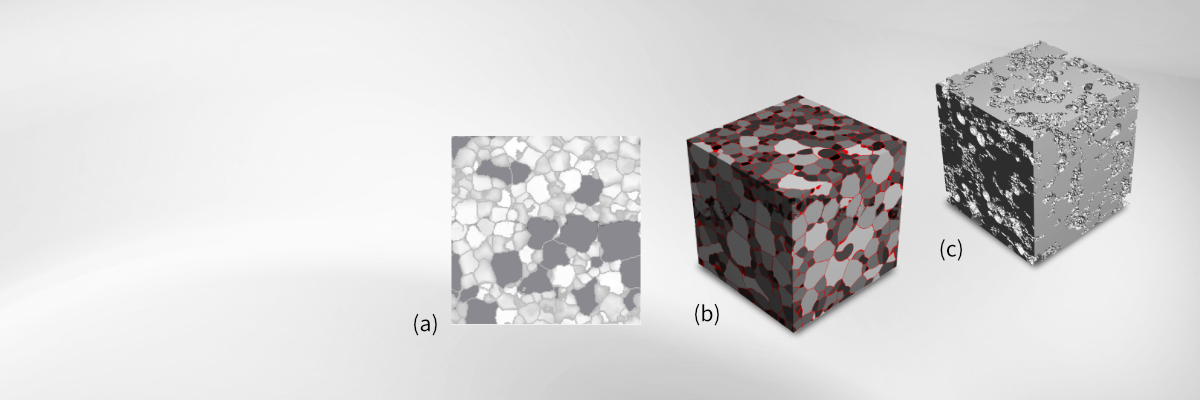

In cases where the statistical input parameters are unknown, our innovative GrainFind module comes into play. Using 3D scans of real materials, GrainFind efficiently determines the needed parameters, ensuring accuracy and reliability in the modeling process.

The resultant digital 3D microstructure model, or Digital Twin, offers an unprecedented level of detail, enabling close analyses comparable to those obtained from traditional µCT-scans. Examples of the analysis capabilities include the computation of pore-size distribution (with the PoroDict module) and the simulation of permeability (with the FlowDict module).

What sets the Digital Twins generated with GeoDict apart is their exceptional versatility. Unlike a single CT-scan, a Digital Twin based on a statistical model proves immensely powerful for digital material design. A Digital Twin allows the exploration of various material structures by digitally manipulating underlying parameters.

GeoDict facilitates a seamless comparison between new designs and existing products. With computed material properties providing valuable insights, this approach enables the creation of entirely new material designs.

GrainGeo includes multiple options to create and modify a granular medium.

Create Grains places grains of a specified shape and size-distribution into a 3D domain until a given solid-volume percentage (or a similar stopping criterion) is reached. The grains are created with overlap, or optionally, are densely packed without overlap. Multiple grain shapes and material phases are possible. Grains may also be created into an pre-existing 3D microstructure model.

The shapes of granular objects are spheres, ellipsoids, general polyhedra with randomly distributed parameters, and even fibers. It is also possible to directly model aggregates; for example, based on carbon particles.

Pile Grains allows to pile grains of a specified shape and size-distribution onto a flat surface or into a pre-existing 3D microstructure model. When piling them, the grains do not overlap each other or the existing geometry. An isolation distance between the grains may be also specified.

Pack and Pile Analytic Spheres allow to create sphere packings with complex size distributions and high packing densities, very close to the theoretical limit.

Stochastic Field Thresholding is based on 3D stochastic fields rather than on grains and grain shapes. Here, an overlay of multiple, e.g. Gaussian random fields, are created and thresholded to match a given solid volume percentage and correlation length.

With Add Binder, it is possible to add realistic binder distributions to an existing 3D microstructure model, e.g. created with the Create Grains command. The binder distribution may be anisotropic, and it can follow a gradient distribution.

Additional options to Grow Sediment, to Sinter, to Roughen Surface, and to Distribute are available, to create even more realistic 3D microstructure models.

Following Modules are often used in combination with GrainGeo:

| Image Processing and Image Analysis | ImportGeo-Vol | ||||

| Material Analysis | GrainFind | PoroDict + MatDict | |||

| Modeling & Design | |||||

| Simulation & Prediction | BatteryDict | ConductoDict | DiffuDict | ElastoDict | FlowDict |

Suitable modules depend on the concrete application.